Willkommen bei der Friedrich W. Löbbe GmbH!

Unser Unternehmen besteht aus zwei Bereichen: Automation & Drives und Heating & Cooling Systems. Obwohl diese beiden Abteilungen unabhängig voneinander arbeiten und unterschiedliche Produkte und Lösungen anbieten, haben sie doch ein gemeinsames Ziel: die Unterstützung von unseren Kunden durch innovative und zuverlässige Technologien. Wir sind stolz darauf, unseren Kunden weltweit hochwertige Produkte und Dienstleistungen anzubieten, die ihren spezifischen Anforderungen entsprechen.

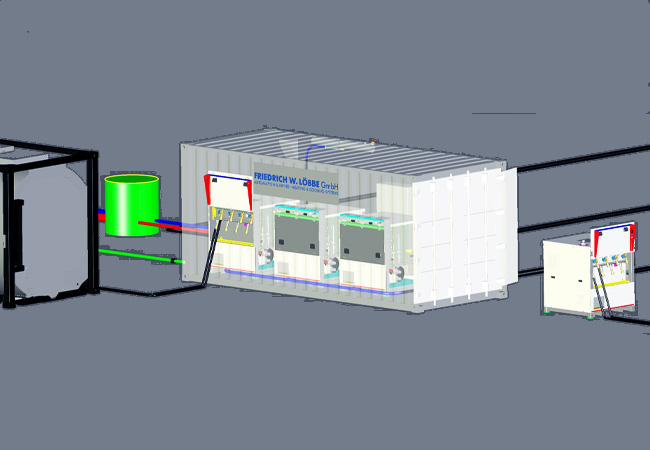

Die Friedrich W. Löbbe GmbH ist das weltmarktführende Unternehmen im Bereich der Entwicklung und Herstellung von Heiz- und Kühlsystemen für Tankcontainer. Seit unserer Gründung im Jahre 1982 haben wir uns auf die Herstellung von Systemen spezialisiert, die eine präzise Temperierung der Kundenprodukte gewährleisten. Unser breites Angebot umfasst verschiedene Systeme für unterschiedliche Anforderungen: von Kühlsystemen, über autarke Heizsysteme, bis hin zu Hochleistungsheizsystemen und noch vieles mehr.

Übersicht Systeme

Vollintegriert oder extern und transportabel – zur Zeit stehen Ihnen 15 verschiedene Systeme zur Auswahl.

Konfigurator

Sie interessieren sich für unsere Systeme, wissen aber noch nicht genau welches sich für Sie eignet? Hier geht es zum Konfigurator.

Service

Fachgerechte Inbetriebnahme, Wartung und Reparatur gehört zu unseren Serviceleistungen.

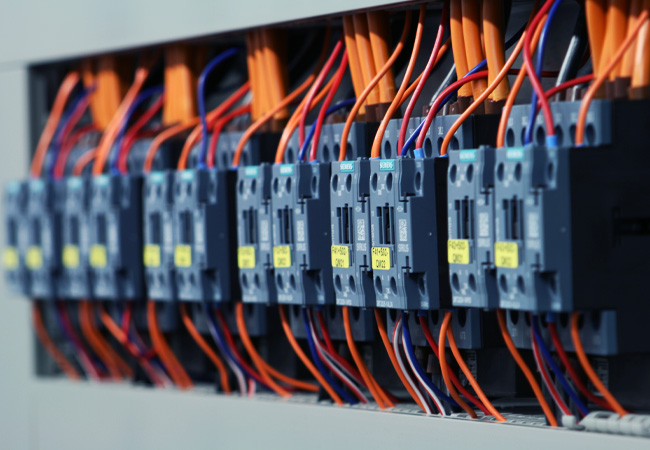

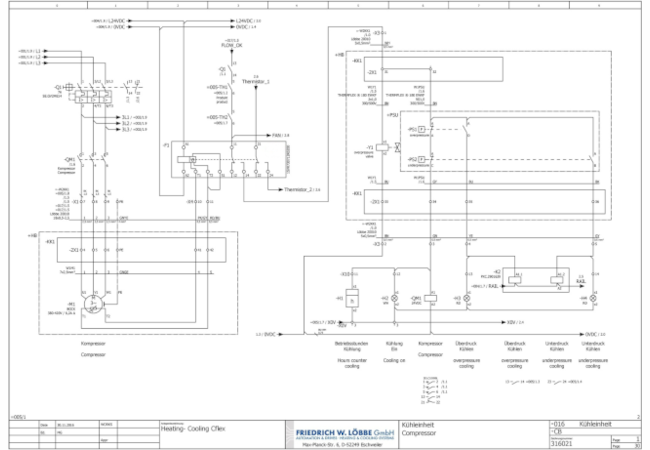

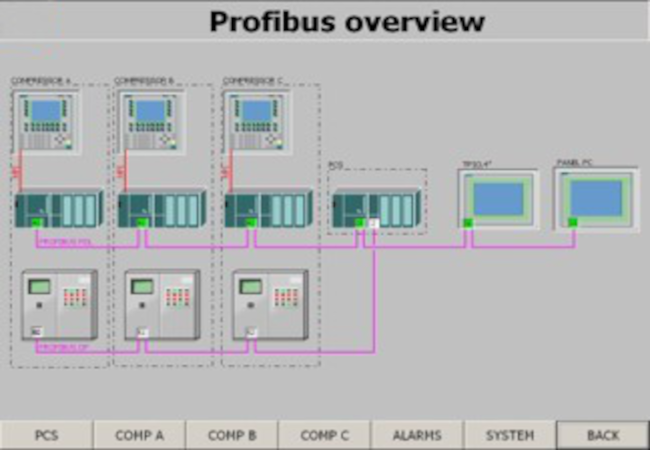

Als langjähriger Anbieter von Lösungen und Systemen für die Automatisierung und Antriebstechnik unterstützen wir Unternehmen dabei , ihre Prozesse effizienter, produktiver und nachhaltiger zu gestallten. Dabei bieten wir ein breites Spektrum an Produkten und Dienstleistungen an, die auf die individuellen Bedürfnisse unserer Kunden zugeschnitten sind. Von der Planung und Projektierung bis hin zur Implementierung und Wartung bieten wir Ihnen alles aus einer Hand.