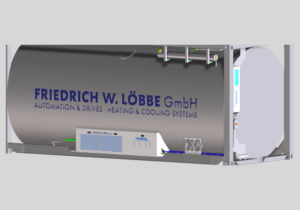

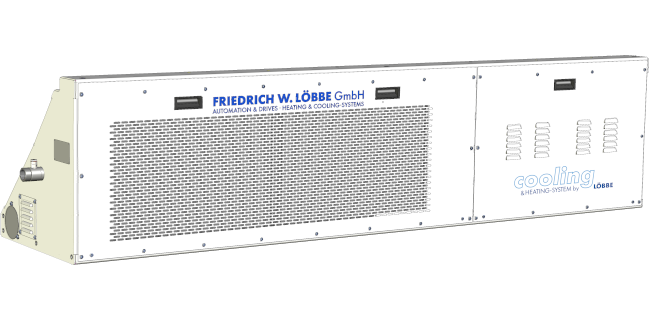

cflex cooling and optional heating system for tank containers

Our cflex system is a cooling system with an optionally expandable heating function. The system has been designed as a fully integrated solution on the tank container and is compatible with almost all tank containers on the market – also for retrofitting. Modular in design, the system is in the result an individual and also maintenance-friendly design with many expansion options.

Function:

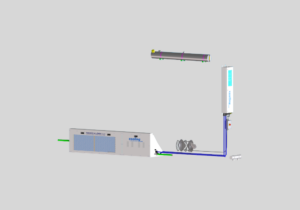

cflex tempers the tank contents indirectly via the outer wall of the container. For this purpose, the circulation pump conveys a heat transfer medium in a closed circuit through the half-pipes, which are normally used for steam heating. The heat transfer medium is a food-sanitary glycol-water mixture. cflex is connected directly to the half-pipes normally used for steam heating, thus creating a closed circuit.

cflex has a cooling system consisting of a refrigeration compressor and a plate heat exchanger as standard. In cooling mode, the heat exchanger extracts thermal energy from the glycol-water mixture, which is strictly separated from the customer’s product.

In the optional heating mode, the electric heater integrated in the system heats the heating medium. The heating of the heat transfer fluid is carried out according to the principle of a continuous flow heater, whereby the fluid is strictly separated from the customer’s product.

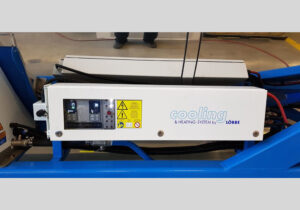

Power for the system is supplied via an industry standard 380-440 V CEE plug.

Cooling and heating are fully automatic. The flow temperature at which the cooling/heating medium flows into the container’s pipe circuit can be set with high precision. This means that even very temperature-sensitive products are protected from quality losses due to contact temperatures that are too high or too low.