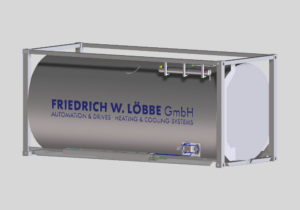

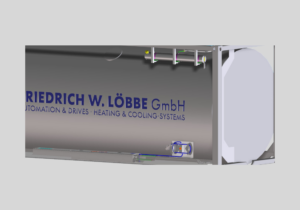

gflexHP high-power heating system for tank containers

Our system series gflexLC, gflex & gflexHP are pure electric heating systems. All three systems are compatible with almost all tank containers on the market – also for retrofitting. Modular in design, the result of each system is an individual and also maintenance-friendly design with many expansion options.

Function:

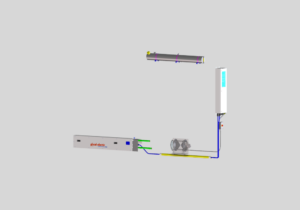

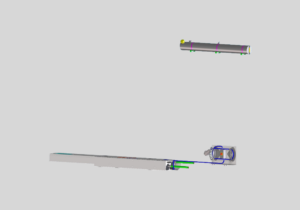

gflexLC, gflex & gflexHP temper the tank contents indirectly via the outer wall of the container. For this purpose, the circulation pump conveys a heat transfer medium in a closed circuit through the half-pipes, which are normally used for steam heating. The heat transfer medium is a food-hygienically safe glycol-water mixture. The electric heater installed in our system, with one or optionally two heating elements, is part of the closed circuit. All components of the three systems are equally reliable and robust.

In heating mode, the electric heater integrated in the system heats the heating medium. The heating of the heat transfer fluid is carried out according to the principle of a continuous flow heater, thereby the fluid is strictly separated from the customer’s product. The power supply for the system is provided by an industry standard 380-440V CEE plug. Heating is fully automatic. The flow temperature at which the heat transfer medium flows into the container’s pipe circuit can be set with high precision. As a result, even very temperature-sensitive products are protected from loss of quality due to too high contact temperatures.

gflexHP is the high-power system of the system series. Thanks to the higher performance, the flow temperature is reached particularly quickly. gflexHP and gflex share some of the basic features. These include, for example, the high-quality stainless steel three-phase pump, which allows the system to operate in an outdoor temperature range of up to -20°C, a flow temperature of up to 95°C – optionally up to 110°C, and multi-voltage capability. However, there are significant differences, gflexHP generally has two heating elements and also more power (38kW). In addition, a microflexPLC is always installed as the control system. This is leads to the further advantages of extended (safety) functions (TRM, SFM, PCM, DBM, EcM), as well as extended remote maintenance and extended telematic functions which are achieved by a combination with our teleflex telematic system.